--

Product Description

Can have one or more closed hole, wall thickness and uniform cross section, in a straight line shape or roll into a delivery. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agricultural, electrical and mechanical industry, household, etc

Features

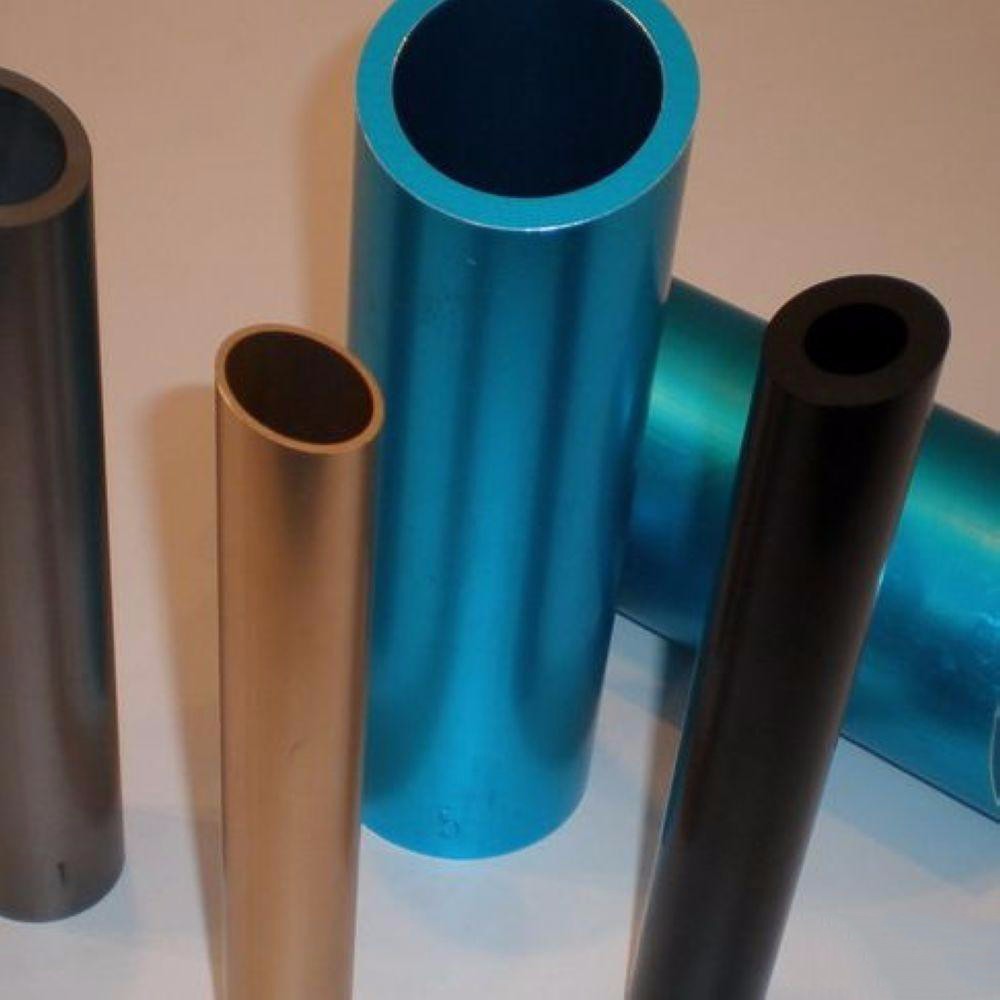

Hard aluminum as a kind of high strength, heat treatment can be improved, after annealing, quenching and thermal plasticity under medium, spot welding good weldability, with gas welding and argon arc welding aluminium tubes have a tendency to form intergranular crack; Aluminum tube after quenching and cold work hardening is cutting performance is good, bad when annealed state. Corrosion resistance is not high, often USES the method of anodic oxidation treatment and paint or surface clad aluminum layer in order to improve the corrosion resistance. Can also be used as mould material.

Advantage of aluminium tube: one is the welding technical advantages: suitable for industrialized production of thin wall copper aluminum pipe welding technology, known as a world-class problem, air conditioner connecting pipe is the key technology of aluminum and copper.

Secondly, the service life of advantage: from the point of aluminum tube wall, due to the refrigerant does not contain water, copper aluminum connecting pipe wall corrosion phenomenon will not occur.

Three is the advantage of energy saving: and the house of the connection pipe, the lower the heat transfer efficiency of the energy saving, in other words, the better the heat insulation effect, the province electricity.

Four is bending performance is good, easy to install, switching

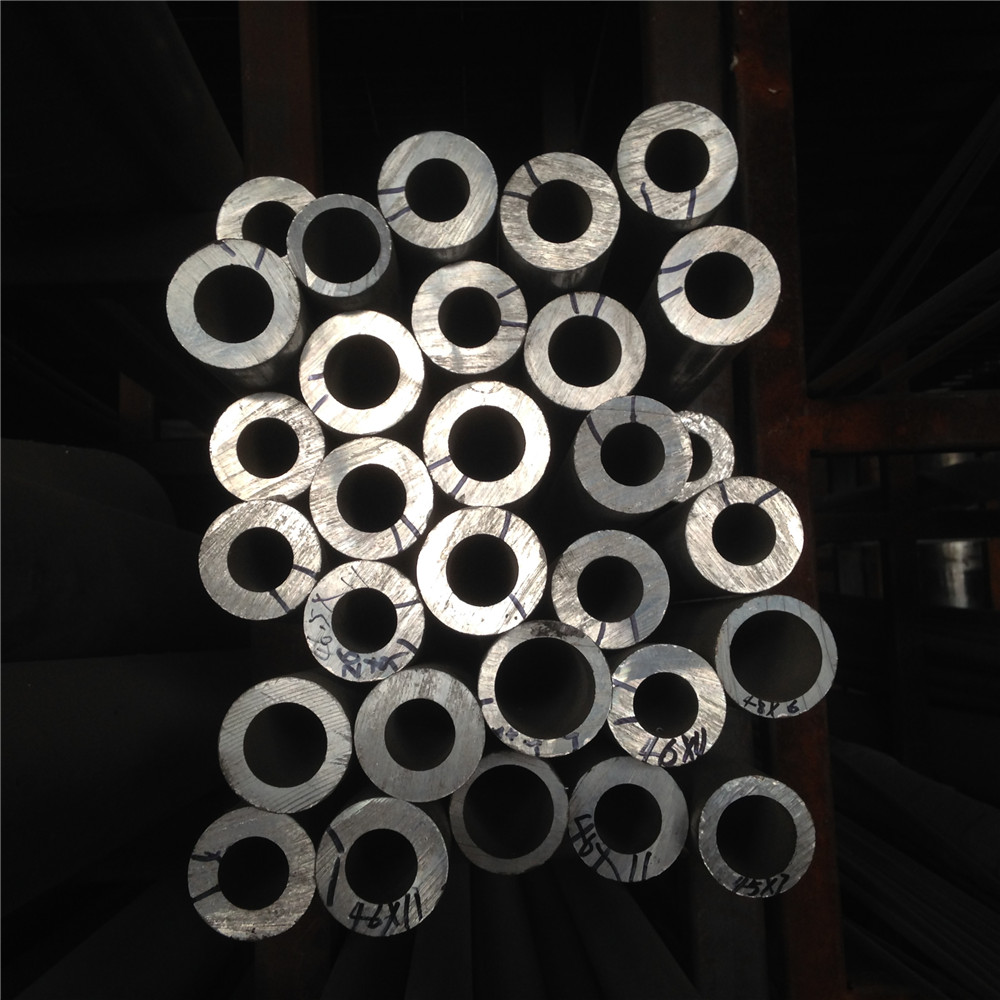

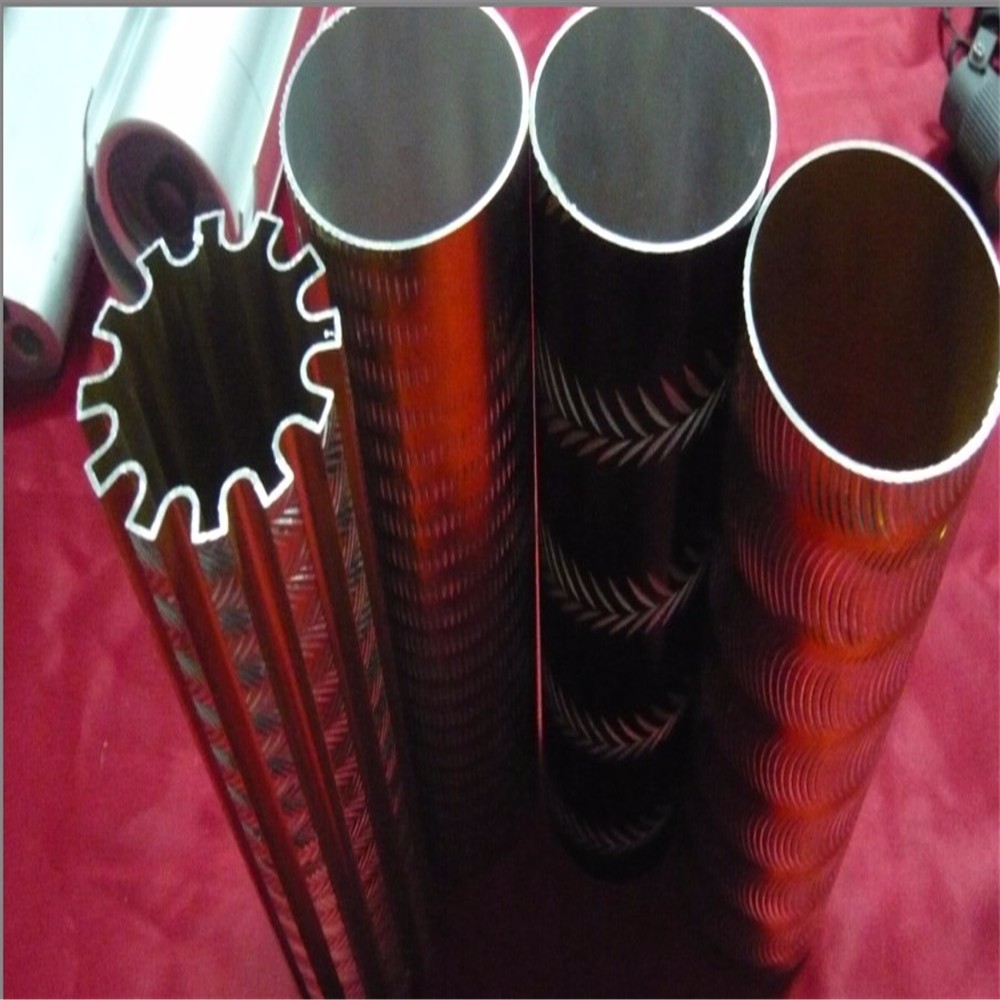

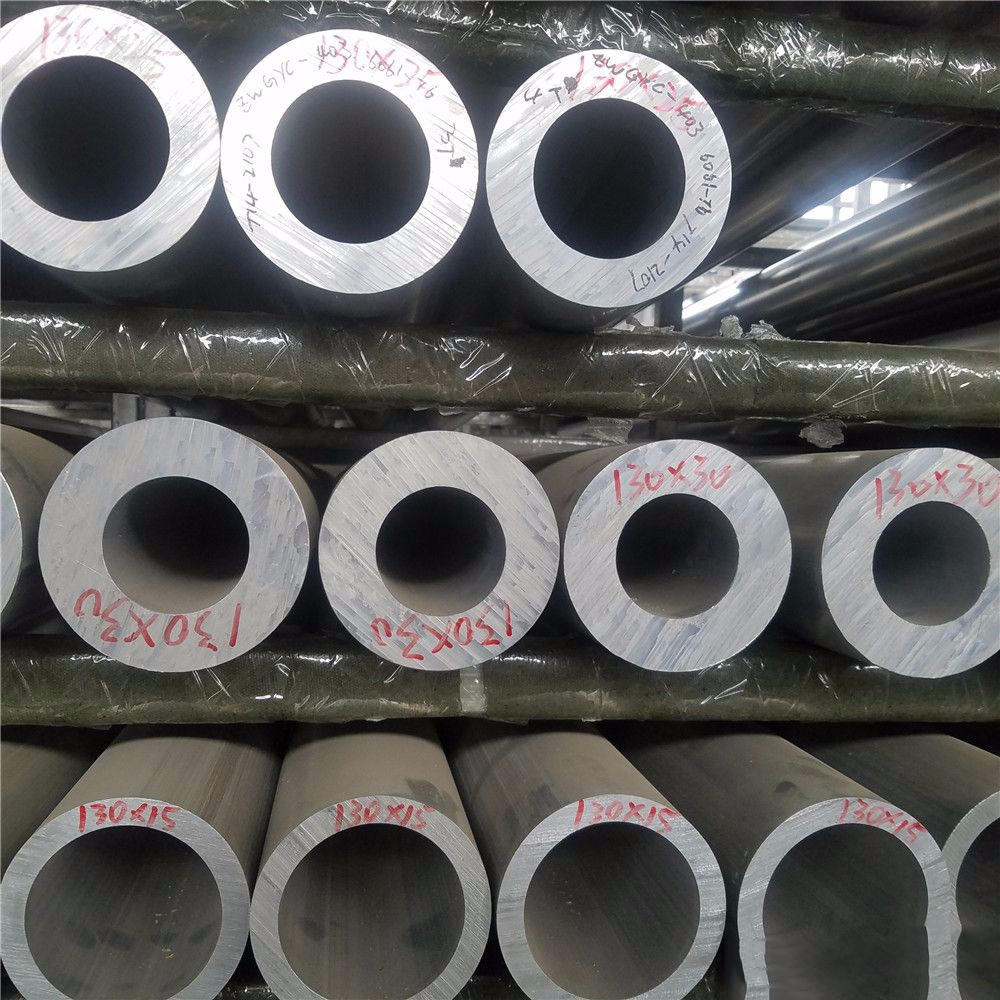

Product display